Dishwasher Malfunctions: Causes and Solutions

Creating a cozy summer home that serves as a peaceful retreat requires careful selection of appliances that enhance comfort without compromising on style or efficiency. At Appliances 4 Less Little Rock, we cater to residents in Little Rock, Benton, Conway, and Pine Bluff with an array of open box, scratch, and dented appliances that are perfect for elevating your summer living. Here’s our guide to the essential appliances for a cozy summer home.

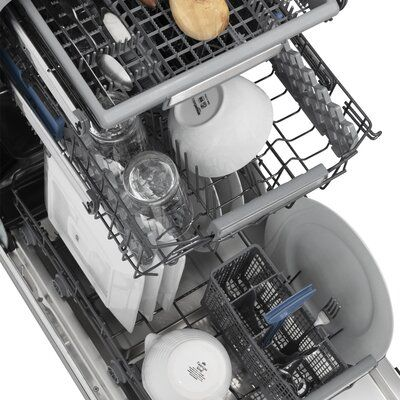

When the dishwasher completes the washing process, the accumulated water cannot be discharged, which will affect the normal use of the equipment. Even with routine cleaning maintenance, drainage problems may recur. Only by understanding the root cause of the non-drainage problem and adopting scientific treatment methods can these 1 failures be effectively solved.

1、Filter system clogging

Fault performance: water accumulation in the cabin after washing, food residue and grease accumulation can be seen around the filter.

Cause analysis: In daily use, food debris, grease and detergent residues will accumulate in the filter and residue basket, forming a physical blockage. These organics can spoil in humid environments, exacerbate clogging and may produce odors.

Solving steps:

·Safety preparation: Be sure to unplug the power plug before handling.

·Take out and clean: Take out the lower bowl and basket and dry the bright water with a dry cloth. Unscrew and remove the filter assembly, thoroughly scrub the filter screen, residue basket and its base groove with a soft brush under running water.

·Check the spray arm: At the same time, check whether the outlet hole of the spray arm is blocked by small particles. If there is any blockage, use a toothpick to dredge it.

·Regular maintenance: It is recommended to perform the above deep cleaning at least once a month to maintain smooth drainage.

2、Drainage pipe problem

Fault manifestations: slow or undrained drainage, may be accompanied by water seepage at the bottom of the machine or pipe connections.

Cause analysis: The drainage hose may be deformed due to aging, excessive bending or being squeezed by heavy objects, resulting in narrow or complete blockage of the internal passage. The inside of the pipe is also easy to adhere to grease and fiber, forming a stubborn blockage.

Solving steps:

·Check the pipeline: turn off the water source and power supply, and check the drain pipe for visible bending, flattening or aging cracking.

·Dredge the pipe: Remove the drain pipe from both ends of the dishwasher and sink drain, and clean the inside with a 1 long wire or a special pipe dredging brush.

·Correct installation: When reinstalling, ensure that the drain pipe is naturally curved, and its highest point must be lower than the bottom of the dishwasher liner to avoid the formation of “air blockage” leading to poor drainage.

3、Drainage pump fault

Fault performance: when starting the drainage program, there is no pumping sound at the bottom of the machine or only the motor “buzzing” idling sound, unable to drain.

Cause analysis: The pump body may be stuck by foreign bodies such as glass fragments and nut shells, causing the impeller to fail to rotate. Long-term use or abnormal wear may also cause damage to the motor.

Solving steps:

·Preliminary judgment: under the premise of power failure, try to manually rotate the drainage pump impeller (if accessible) under the filter to feel whether there is any jam.

·Clean up foreign objects: if it can rotate but there is resistance, there may be small foreign objects stuck, you can try to clean up.

·Seek professional help: If the impeller cannot rotate at all or rotates flexibly but the motor does not work, the drainage pump may need to be replaced. This operation involves water and electricity safety, and it is strongly recommended to contact professional maintenance personnel to deal with it.

4、Water level sensor fault

Fault performance: The equipment has an error in judging the internal water storage capacity. It may be manifested as continuous water injection when there is no water in the cabin, or the drainage procedure cannot be started normally when there is water accumulation.

Cause analysis: The sensing part of the water pressure switch or electronic sensor used to monitor the water level may be covered by scale or oil formed by minerals in the water, resulting in signal distortion. In addition, the failure of internal components caused by the service life or moisture of the sensor itself, as well as poor contact of the connecting line, are also common reasons.

Processing steps:

·Power off and basic cleaning: Ensure that the equipment is completely powered off. Find the water level sensor, carefully remove it, and gently wipe its sensing contacts and cavity with a soft cloth dipped in citric acid solution or vinegar to remove dirt.

·Check the wiring connection: Visually check the wires and connectors related to the sensor to make sure that they are tightly connected and there is no sign of looseness, corrosion or damage.

·Apply for professional repair: If the fault persists after the above cleaning and inspection, it is most likely that the sensing element is damaged. At this time should stop self-processing, and contact professional and technical personnel for accurate detection and parts replacement.

Conclusion

When the dishwasher has a drain failure, systematic troubleshooting logic is essential. First of all, we should start with the two daily maintenance points of the filtration system and the external drainage pipeline to solve the most common physical blockage problem. If the problem persists, further consideration should be given to whether there is a functional impairment in core components such as the drainage pump or water level sensor. Developing good usage habits is the key to prevention, such as cleaning the filter thoroughly on a regular basis every month. For the judgment and maintenance involving the dismantling of precision parts, circuit testing or the need for special tools, in order to ensure personal safety and ensure the quality of maintenance, it is recommended to seek the help of brand after-sales service or professional maintenance personnel in time to achieve long-term stable work of the equipment.